Nissan Rogue Service Manual: Shift lock system

Component Function Check

1.CHECK SHIFT LOCK OPERATION (PART 1)

- Turn ignition ON.

- Shift the selector lever to “P” position.

- Attempt to shift the selector lever to any other than position with the brake pedal released.

Can the selector lever be shifted to any other position? YES >> Go to TM-183, "Diagnosis Procedure".

NO >> GO TO 2.

2.CHECK SHIFT LOCK OPERATION (PART 2)

Attempt to shift the selector lever to any other than position with the brake pedal depressed.

Can the selector lever be shifted to any other position? YES >> Inspection End.

NO >> Go to TM-183, "Diagnosis Procedure".

Diagnosis Procedure

Regarding Wiring Diagram information, refer to TM-75, "Wiring Diagram".

1.CHECK STOP LAMP SWITCH

- Ignition switch ON.

- Check voltage between stop lamp switch connector E38 terminal 4 and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 4.

2.CHECK CVT SHIFT SELECTOR

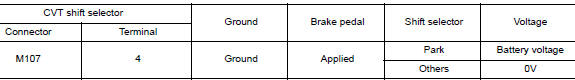

Check voltage between CVT shift selector connector M107 terminal 4 and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 5.

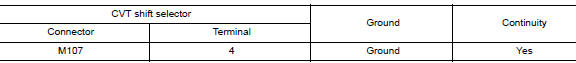

3.CHECK GROUND CIRCUIT

- Ignition switch OFF.

- Disconnect CVT shift selector connector.

- Check continuity between CVT shift selector connector M107 terminal 4 and ground.

Is the inspection result normal? YES >> Replace CVT shift selector. Refer to TM-194, "Removal and Installation".

NO >> Repair or replace harness.

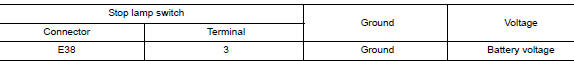

4.CHECK STOP LAMP SWITCH POWER CIRCUIT

Check voltage between stop lamp switch connector E38 terminal 3 and ground.

Is the inspection result normal? YES >> Replace stop lamp switch. Refer to BR-20, "Exploded View".

NO >> Repair or replace harness.

5.CHECK CVT SHIFT SELECTOR POWER CIRCUIT

Check voltage between CVT shift selector connector M107 terminal 3 and ground.

Is the inspection result normal? YES >> Replace CVT shift selector. Refer to TM-194, "Removal and Installation".

NO >> Repair or replace harness or connector.

Component Inspection (CVT Shift Selector Assembly)

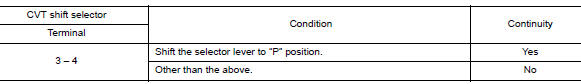

1.CHECK CVT SHIFT SELECTOR ASSEMBLY (PART 1)

Check continuity between CVT shift selector connector terminals.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace CVT shift selector assembly. Refer to TM-194, "Removal and Installation".

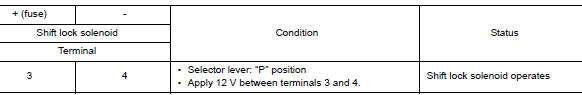

2.CHECK CVT SHIFT SELECTOR ASSEMBLY (PART 2)

Apply voltage to terminals of CVT shift selector and check that shift lock solenoid is activated.

CAUTION:

- Connect the fuse between the terminals when applying the voltage.

- Never cause shorting between terminals.

Is the inspection result normal? YES >> Inspection End NO >> Replace CVT shift selector assembly. Refer to TM-194, "Removal and Installation".

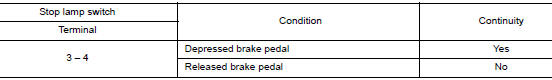

Component Inspection (Stop Lamp Switch)

1.CHECK STOP LAMP SWITCH

Check continuity between the stop lamp switch connector terminals.

Is the inspection result normal? YES >> Inspection End.

NO >> Replace stop lamp switch. Refer to BR-20, "Exploded View".

Shift position indicator circuit

Shift position indicator circuit

Component Parts Function Inspection

1.CHECK SHIFT POSITION INDICATOR

Start the engine.

Shift selector lever.

Check that the selector lever position and the shift position

...

Symptom diagnosis

Symptom diagnosis

CVT CONTROL SYSTEM

Symptom Table

The diagnosis item number indicates the order of check. Start checking

in the order from 1.

Perform diagnoses of symptom table 1 before symptom table 2 ...

Other materials:

Periodic maintenance

IDLE SPEED

Inspection

1.CHECK IDLE SPEED

With CONSULT

Check idle speed in “DATA MONITOR” mode of “ENGINE” using CONSULT.

With GST

Check idle speed with Service $01 of GST.

>> INSPECTION END

IGNITION TIMING

Inspection

1.CHECK IGNITION TIMING

Attach timing light (A) to th ...

CAN system (type 5)

MAIN LINE BETWEEN IPDM-E AND DLC CIRCUIT

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the following terminals and connectors for damage, bend and

loose connection (connector side

an ...

Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow (With GR8-1200 NI)

STARTING SYSTEM DIAGNOSIS WITH GR8-1200 NI

To test the starting system, use the following special service tool:

GR8-1200 NI Multitasking battery and electrical diagnostic station

NOTE:

Refer to the diagnostic station Instruc ...