Nissan Rogue Service Manual: Stall test

Work Procedure

INSPECTION

- Check the engine oil level. Replenish if necessary. Refer to LU-7, "Inspection".

- Check for leak of the CVT fluid. Refer to TM-190, "Inspection".

- Drive for about 10 minutes to warm up the vehicle so that the CVT fluid temperature is 50 to 80°C (122 to 176°F).

- Be sure to apply the parking brake and block the tires.

- Start the engine, depress the brake pedal and put the selector lever to the D position.

- While depressing the brake pedal, depress the accelerator pedal gradually.

- Read the stall speed quickly. Then, release your foot from the accelerator pedal quickly.

CAUTION: Do not depress the accelerator pedal for 5 seconds or more during the test.

Stall speed : Refer to TM-226, "Stall Speed".

- Place the selector lever in the N position.

- Cool the CVT fluid.

CAUTION: Run the engine with the idle speed for at least 1 minute.

- Put the selector lever to the R position and perform Step 6 to Step 9 again.

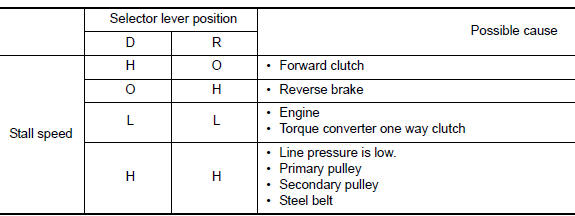

NARROWING-DOWN MALFUNCTIONING PARTS

O: Within the stall speed standard value.

H: Stall speed is higher than the standard value.

L: Stall speed is lower than the standard value.

CVT fluid cooler system

CVT fluid cooler system

Cleaning

Whenever an automatic transaxle is repaired, overhauled, or replaced, the CVT

fluid cooler mounted in the

radiator must be inspected and cleaned.

Metal debris and friction material, if ...

CVT position

CVT position

Inspection

Turn ON the ignition switch with the shift selector at the “P” position.

Press the shift selector button with the brake pedal depressed,

and confirm that the shift select ...

Other materials:

Warning lights

For additional information on warnings and indicators,

refer to “Vehicle information display” in

this section.

Anti-lock

Braking System (ABS) warning lig

When the ignition switch is placed in the ON

position, the ABS warning light illuminates and

then turns off. This indicates the ...

Basic inspection

DIAGNOSIS AND REPAIR WORK FLOW

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.GET INFORMATION FOR SYMPTOM

Get detailed information from the customer about the symptom (the

condition and the environment when

the incident/malfunction occurs).

Check operation condition of the ...

Diagnosis and repair work flow

Work Flow

NOTE:

“DTC” includes DTC at the 1st trip.

1.OBTAIN INFORMATION ABOUT SYMPTOM

Refer to TM-80, "Diagnostic Work Sheet" and interview the customer to obtain

the malfunction information

(conditions and environment when the malfunction occurred) as much as possible

when t ...