Nissan Rogue Service Manual: P0705 transmission range sensor A

DTC Description

DTC DETECTION LOGIC

| DTC | CONSULT screen terms (Trouble diagnosis content) | DTC detection condition |

| P0705 | T/M RANGE SENSOR A [Transmission Range Sensor A Circuit (PRNDL Input)] | When all of the following conditions are satisfied and this state is

maintained

for 2 seconds:

|

POSSIBLE CAUSE

- Harness or connector (Short circuit between transmission range switch and TCM)

- Transmission range switch

FAIL-SAFE

- Shift position indicator on combination meter is not displayed

- Selector shock is large

- Start is slow

- Acceleration is slow

- Lock-up is not performed

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

- Turn ignition switch ON.

- Shift the selector lever through entire positions from “P” to “L”. (Hold the selector lever at each position for 5 seconds or more.)

- Check the first trip DTC.

Is “P0705” detected? YES >> Go to TM-107, "Diagnosis Procedure".

NO-1 >> To check malfunction symptom before repair: Refer to GI-41, "Intermittent Incident".

NO-2 >> Confirmation after repair: INSPECTION END

Diagnosis Procedure

1.CHECK TCM INPUT SIGNALS

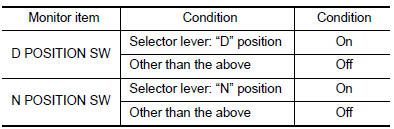

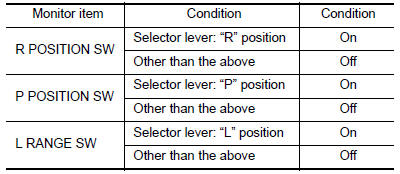

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “Data Monitor” in “TRANSMISSION”.

- Select “D POSITION SW”, “N POSITION SW”, “R POSITION SW”, “P POSITION SW” and “L RANGE SW”.

- Shift the selector lever through entire positions from “P” to “L” and check ON/OFF of each monitor item.

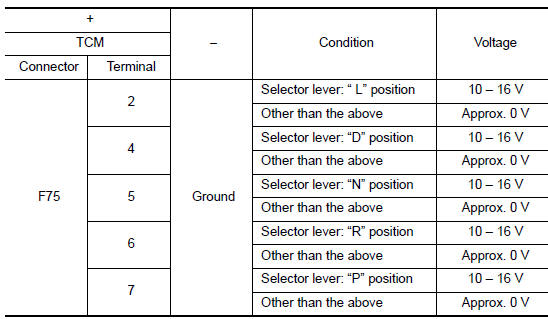

Without CONSULT

Without CONSULT

- Turn ignition switch OFF.

- Disconnect TCM connector.

- Turn ignition switch ON.

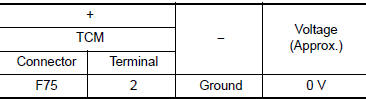

- Shift the selector lever from “P” to “L” and check voltage between TCM harness connector terminals and ground.

Is the inspection result normal? YES >> INSPECTION END

NO-1 [“D POSITION SW” is “ON” when selector is not in “D” position. (Or connector terminal 4 is at power voltage.)]>>GO TO 2.

NO-2 [“N POSITION SW” is “ON” when selector is not in “N” position. (Or connector terminal 5 is at power voltage.)]>>GO TO 4.

NO-3 [“R POSITION SW” is “ON” when selector is not in “R” position. (Or connector terminal 6 is at power voltage.)]>>GO TO 6.

NO-4 [“P POSITION SW” is “ON” when selector is not in “P” position. (Or connector terminal 7 is at power voltage.)]>>GO TO 8.

NO-5 [“L POSITION SW” is “ON” when selector is not in “L” position. (Or connector terminal 2 is at power voltage.)]>>GO TO 10.

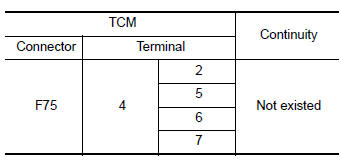

2.CHECK D POSITION SW CIRCUIT (PART 1)

- Turn ignition switch OFF.

- Disconnect TCM connector.

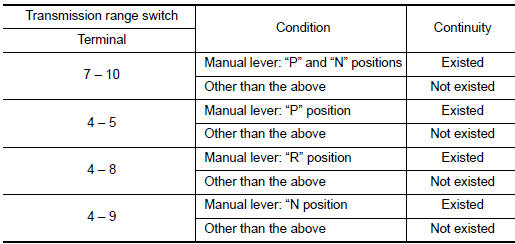

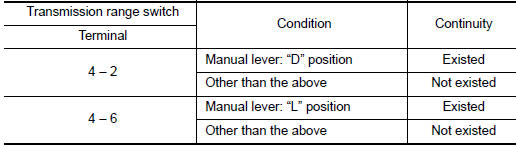

- Check continuity between TCM harness connector terminals.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace malfunctioning parts.

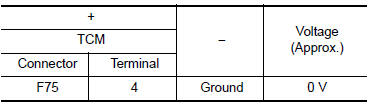

3.CHECK D POSITION SW CIRCUIT (PART 2)

- Disconnect transmission range switch connector.

- Turn ignition switch ON.

- Check voltage between TCM harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 12.

NO >> Repair or replace malfunctioning parts.

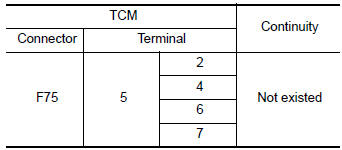

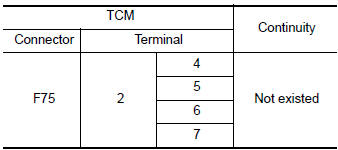

4.CHECK N POSITION SW CIRCUIT (PART 1)

- Turn ignition switch OFF.

- Disconnect TCM connector.

- Check continuity between TCM harness connector terminals.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace malfunctioning parts.

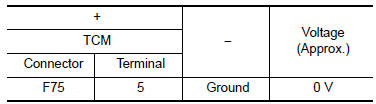

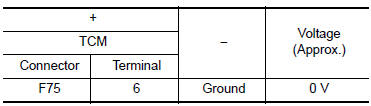

5.CHECK N POSITION SW CIRCUIT (PART 2)

- Disconnect transmission range switch connector.

- Turn ignition switch ON.

- Check voltage between TCM harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 12.

NO >> Repair or replace malfunctioning parts.

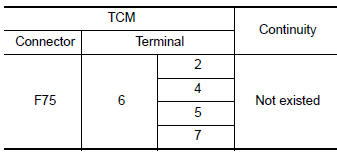

6.CHECK P POSITION SW CIRCUIT (PART 1)

- Turn ignition switch OFF.

- Disconnect TCM connector.

- Check continuity between TCM harness connector terminals.

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair or replace malfunctioning parts.

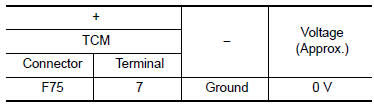

7.CHECK P POSITION SW CIRCUIT (PART 2)

- Disconnect transmission range switch connector.

- Turn ignition switch ON.

- Check voltage between TCM harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 12.

NO >> Repair or replace malfunctioning parts.

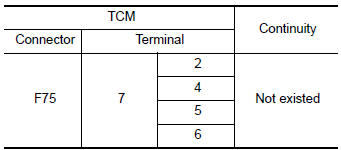

8.CHECK R POSITION SW CIRCUIT (PART1)

- Turn ignition switch OFF.

- Disconnect TCM connector.

- Check continuity between TCM harness connector terminals.

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair or replace malfunctioning parts.

9.CHECK R POSITION SW CIRCUIT (PART 2)

- Disconnect transmission range switch connector.

- Turn ignition switch ON.

- Check voltage between TCM harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 12.

NO >> Repair or replace malfunctioning parts.

10.CHECK L POSITION SWITCH CIRCUIT (PART 1)

- Turn ignition switch OFF.

- Disconnect TCM connector.

- Check continuity between TCM harness connector terminals.

Is the inspection result normal? YES >> GO TO 11.

NO >> Repair or replace malfunctioning parts.

11.CHECK L POSITION SWITCH CIRCUIT (PART 2)

- Disconnect transmission range switch connector.

- Turn ignition switch ON.

- Check voltage between TCM harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 12.

NO >> Repair or replace malfunctioning parts.

12.CHECK TRANSMISSION RANGE SWITCH

Check transmission range switch. Refer to TM-111, "Component Inspection".

Is the check result normal? YES >> INSPECTION END

NO >> Repair or replace malfunctioning parts.

Component Inspection

1.CHECK TRANSMISSION RANGE SWITCH

Check continuity between transmission range switch connector terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> There is a malfunction of transmission range switch. Replace transaxle assembly. Refer to TM- 205, "Removal and Installation".

P062F EEPROM

P062F EEPROM

Description

TCM compares the calculated value stored in the flash ROM with the value

stored in TCM. If the calculated

value does not agree with the stored value, TCM judges this as a malfunction.

...

P0706 transmission range sensor A

P0706 transmission range sensor A

DTC Description

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P0706

T/M RANGE SENSOR A

(Transmission Range Sensor A ...

Other materials:

Monitor, climate, audio, phone and voice recognition systems

WARNING

Positioning of the heating or air conditioning

controls and display controls

should not be done while driving in order

that full attention may be given to

the driving operation.

Do not disassemble or modify this system.

If you do, it may result ...

Liquid Gasket

REMOVAL OF LIQUID GASKET SEALING

After removing the bolts and nuts, separate the mating surface and

remove the liquid gasket using Tool (A).

Tool Number : KV10111100 (J-37228)

CAUTION:

Be careful not to damage the mating surfaces.

In areas where the cutter is difficult to use, u ...

CAN system (type 2)

MAIN LINE BETWEEN IPDM-E AND DLC CIRCUIT

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the following terminals and connectors for damage, bend and

loose connection (connector side

an ...