Nissan Rogue Service Manual: Power supply and ground circuit

BCM (BODY CONTROL SYSTEM) (WITH INTELLIGENT KEY SYSTEM)

BCM (BODY CONTROL SYSTEM) (WITH INTELLIGENT KEY SYSTEM) : Diagnosis Procedure

Regarding Wiring Diagram information, refer to BCS-50, "Wiring Diagram".

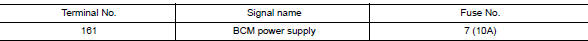

1. CHECK FUSE

Check that the following fuse is not blown.

Is the fuse blown? YES >> Replace the blown fuse after repairing the affected circuit.

NO >> GO TO 2.

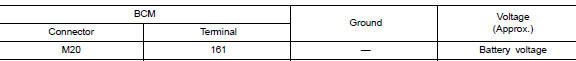

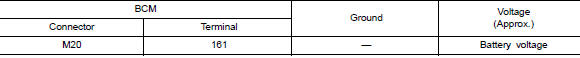

2. CHECK POWER SUPPLY CIRCUIT

- Disconnect BCM connector M20.

- Check voltage between BCM connector M20 and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness or connectors.

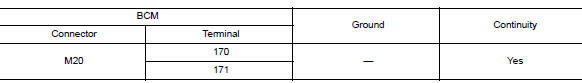

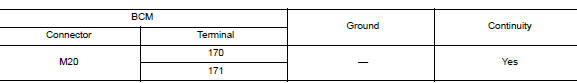

3. CHECK GROUND CIRCUIT

Check continuity between BCM connector M20 and ground.

Is the inspection result normal? YES >> Inspection End.

NO >> Repair or replace harness or connectors.

BCM (BODY CONTROL SYSTEM) (WITHOUT INTELLIGENT KEY SYSTEM)

BCM (BODY CONTROL SYSTEM) (WITHOUT INTELLIGENT KEY SYSTEM) : Diagnosis Procedure

Regarding Wiring Diagram information, refer to BCS-110, "Wiring Diagram".

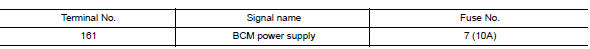

1. CHECK FUSE

Check that the following fuse is not blown.

Is the fuse blown? YES >> Replace the blown fuse after repairing the affected circuit.

NO >> GO TO 2.

2. CHECK POWER SUPPLY CIRCUIT

- Disconnect BCM connector M20.

- Check voltage between BCM connector M20 and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness or connectors.

3. CHECK GROUND CIRCUIT

Check continuity between BCM connector M20 and ground.

Is the inspection result normal? YES >> Inspection End.

NO >> Repair or replace harness or connectors.

MOONROOF MOTOR ASSEMBLY

MOONROOF MOTOR ASSEMBLY : Description

- BCM supplies the moonroof motor assembly with power.

- CPU is integrated in moonroof motor assembly.

- Tilts up/down & slides open/close by moonroof switch operation.

- In order to close the moonroof during high speed driving, the Combination meter will send a speed signal to the moonroof CPU to adjust the torque of the motor during the tilt-down operation.

MOONROOF MOTOR ASSEMBLY : Component Function Check

1. CHECK MOONROOF MOTOR FUNCTION

Does the tilt up/down & slide open/close functions operate normally with moonroof switch? Is the inspection result normal? YES >> Moonroof motor assembly is OK.

NO >> Refer to RF-26, "MOONROOF MOTOR ASSEMBLY : Diagnosis Procedure".

MOONROOF MOTOR ASSEMBLY : Diagnosis Procedure

Regarding Wiring Diagram information, refer to RF-17, "Wiring Diagram".

MOONROOF MOTOR ASSEMBLY

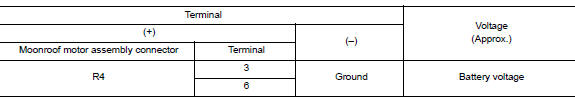

1. CHECK POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect the moonroof motor assembly connector.

- Turn ignition switch ON.

- Check voltage between moonroof motor assembly connector and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 3.

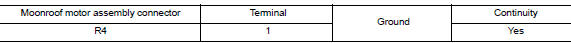

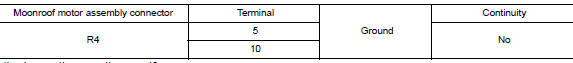

2. CHECK GROUND CIRCUIT

- Turn ignition switch OFF.

- Check continuity between moonroof motor assembly connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace harness.

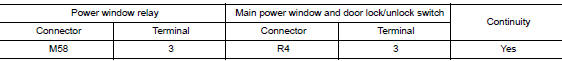

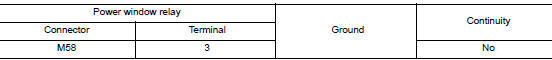

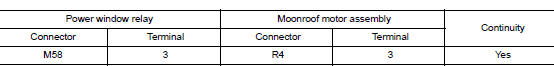

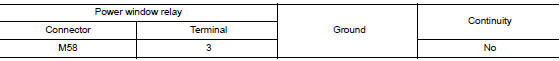

3.CHECK HARNESS CONTINUITY

- Turn ignition switch OFF.

- Disconnect power window relay connector.

- Check continuity between power window relay harness connector and moonroof motor assembly harness connector.

- Check continuity between power window relay harness connector and ground.

Is the inspection result normal? YES >> Refer to PWC-48, "Diagnosis Procedure".

NO >> Repair or replace harness.

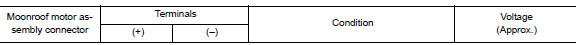

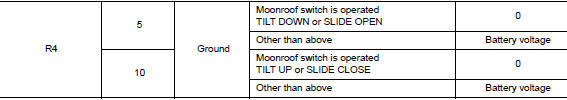

4. CHECK MOONROOF SWITCH INPUT SIGNAL

- Connect moonroof motor assembly.

- Turn ignition switch ON.

- Check voltage between the moonroof motor assembly connector and ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 6.

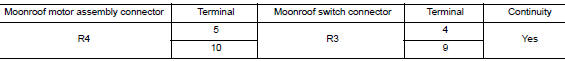

5. CHECK MOONROOF SWITCH CIRCUIT

- Turn ignition switch OFF.

- Disconnect the moonroof motor assembly and moonroof switch.

- Check continuity between the moonroof motor assembly connector and moonroof switch connector.

- Check continuity between the moonroof motor assembly connector and ground.

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair or replace harness.

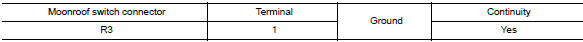

6. CHECK MOONROOF SWITCH GROUND CIRCUIT

- Connect moonroof motor assembly.

- Check continuity between the moonroof switch connector and ground.

Is the inspection result normal? YES >> Refer to RF-32, "Component Inspection".

NO >> Repair or replace harness.

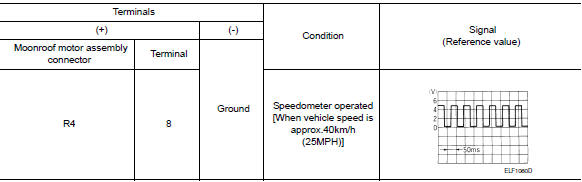

7. CHECK COMBINATION METER SIGNAL

- Connect the moonroof motor assembly connector.

- Turn ignition switch ON.

- Check the signal between the moonroof motor assembly connector and ground with oscilloscope.

Is the inspection result normal? YES >> Replace moonroof motor assembly. Refer to RF-53, "Removal and Installation". After that, refer to RF-24, "ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Requirement".

NO >> GO TO 9.

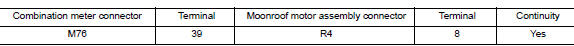

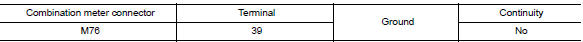

8.CHECK COMBINATION METER CIRCUIT

- Turn ignition switch OFF.

- Disconnect combination meter.

- Check continuity between the combination meter connector and the moonroof motor assembly connector.

- Check continuity between the combination meter connector and ground.

Is the inspection result normal? YES >> Replace combination meter. Refer to BCS-76, "Removal and Installation".

NO >> Repair or replace harness.

MOONROOF MOTOR ASSEMBLY : Special Repair Requirement

1. PERFORM INITIALIZATION PROCEDURE

Perform the initialization procedure.

Refer to RF-29, "MOONROOF MOTOR ASSEMBLY : Special Repair Requirement".

>> GO TO 2.

2. CHECK ANTI-PINCH OPERATION

Check the anti-pinch operation.

Refer to RF-29, "MOONROOF MOTOR ASSEMBLY : Special Repair Requirement".

Is the inspection result normal? YES >> Inspection End.

NO >> Check fitting adjustment.

SUNSHADE MOTOR ASSEMBLY

SUNSHADE MOTOR ASSEMBLY : Description

- BCM supplies the sunshade motor assembly with power.

- CPU is integrated in sunshade motor assembly.

- Slide open/close controlled by the moonroof switch operation.

SUNSHADE MOTOR ASSEMBLY : Component Function Check

1. CHECK SUNSHADE MOTOR FUNCTION

Does the slide open and close functions operate normally with the moonroof switch? Is the inspection result normal? YES >> Sunshade motor assembly is OK.

NO >> Refer to RF-29, "SUNSHADE MOTOR ASSEMBLY : Diagnosis Procedure".

SUNSHADE MOTOR ASSEMBLY : Diagnosis Procedure

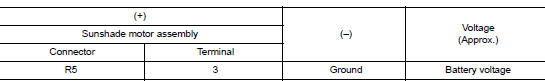

1.CHECK POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect sunshade motor assembly connector.

- Turn ignition switch ON.

- Check voltage between sunshade motor assembly harness connector and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 3.

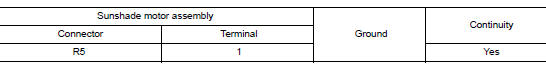

2.CHECK GROUND CIRCUIT

- Turn ignition switch OFF.

- Check continuity between sunshade motor assembly harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace the harness.

3.CHECK HARNESS CONTINUITY

- Turn ignition switch OFF.

- Disconnect power window relay connector.

- Check continuity between power window relay harness connector and moonroof motor assembly harness connector.

- Check continuity between power window relay harness connector and ground.

Is the inspection result normal? YES >> Refer to PWC-48, "Diagnosis Procedure".

NO >> Repair or replace harness.

Moonroof switch

Moonroof switch

Description

Transmits switch operation signal to moonroof motor and sunshade motor

assembly.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to RF-17, "Wiring Diagram".

...

Other materials:

P1078 EVT control position sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P1078

EXH TIM SEN/CIRC-B1

(EXH TIM SEN/CIRC-B1)

An excessively high or low voltage from the sensor is sent to ECM.

POSSIBLE CAUSE

H ...

Preparation

PREPARATION

Special Service Tool

The actual shape of the tools may differ from those illustrated here.

Tool number

(TechMate No.)

Tool name

Description

KV40107300

( — )

Boot band crimping tool

Installing boot band

KV40107500

( — )

...

P050A, P050B, P050E cold start control

Description

ECM controls ignition timing and engine idle speed when engine is started

with pre-warming up condition.

This control promotes the activation of three way catalyst by heating the

catalyst and reduces emissions.

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT scre ...